At Enerfac LLC, we are proud of the work we have done. It stands as a testament to type of care and attention we will generate for your project.

We are engineering and consulting industry leaders whose record of success is fully illustrated below

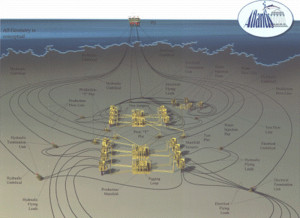

- BP ATLANTIS GoM USA

Overall Project Scope

- Semi-submersible in 2000m water depth

- 10-inch/16-inch pipe-in-pipe production system

- 10-inch Water injection lines

- Flow lines and SCR Design and Project Management

- SCR Pipe QA/QC, Matching and Tracking

- SCR Installation Interface Design and Management

- Inspection of PQ Load-out

Energy Facility® provided the following:

- Design Consultancy

- Installation Management

- Project Scheduling

- SCM / Materials Support

- Project Management

- Construction Management

- Inspection

- DISCOVERY PIPELINE SYSTEM

Overall Project Scope

The Discovery Pipeline System was designed and built to bring 600 MMCFD (expandable to over 1 BCFD) of natural gas and more than 7500 BPD of condensate from offshore fields in the Gulf of Mexico to a new gas processing plant in Larose, Louisiana.

The heart of the Discovery Pipeline System is a 105 mile, 30-inch diameter mainline pipeline extending from the edge of the outer continental shelf from a platform at Ewing Bank Block 873 to the new plant site in Larose. The offshore system was built with three lateral pipelines tying into the 30-inch mainline. These include a 26 mile, 18-inch diameter pipeline from Grand Isle Block 115 platform, and a 10 mile, 12-inch diameter pipeline from South Timbalier Block 37 ‘A’ platform.

Two mainline valve stations were constructed along the pipeline route between the shoreline and Larose. A 24-inch diameter pipeline was installed to parallel the 30-inch mainline from the second valve station into the plant. This six mile parallel line provides additional flow capacity into Larose and is used to facilitate pigging operations in the system.

Downstream of the Larose Plant, 20-inch and 30-inch diameter residue pipelines were installed to transport processed gas to nearby distribution systems.

Three existing pipelines also had services converted for the project.

Energy Facility® provided the following:

Complete design engineering, permitting, inspection, construction management, materials sourcing, expediting and C.A.T.S.® (Construction Automated Tracking System) traceability services to the Discovery Partnership for this project. The full scope of work included all pipelines and pipeline conversions, launchers, risers, metering, instrumentation and corrosion protection for the pipeline system.

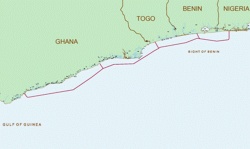

- WEST AFRICAN GAS PIPELINE PROJECT (Nigeria, Benin, Togo, Ghana)

Overall Project Scope

This project consisted of the development of an onshore/offshore gas distribution network delivering gas from Nigeria to commercial customers in the neighboring countries of Benin, Togo, and Ghana.

This project included the installation of a 57 km 30-inch onshore pipeline and onshore compression station in Nigeria, construction of a 579 km offshore pipeline distribution system, and installation of individual regulating and metering stations at each of the four gas receiving points in Cotonou (Benin), Lome (Togo), Tema (Ghana), and Takoradi (Ghana).

The main offshore pipeline was a 20-inch pipe with smaller intermediate distribution spur pipelines sized between 8-inch and 18-inch. The lateral spur pipelines to each of the gas delivery points were tied into the main pipeline section by way of subsea tie-ins. Each landfall transition was horizontally drilled shore crossing.

Enerfac’s Scope of Work

Energy Facility® provided front-end engineering design and drafting services related to the offshore portion of the project. This included all pipelines, subsea tie-ins, and shore crossings. Energy Facility® also developed final route definition, managing and providing on-site inspection for all geophysical and geotechnical survey activities, reviewed project constructability issues, and developed detailed costs and schedules.

Further, Energy Facility® developed risk assessment strategies, execution, contingency, testing and commissioning plans, assisted in all bid development and evaluation, coordinated all interface work between the onshore and offshore work, assisted in resolution of both HES issues and regulatory requirements, and provided input for EIA development.

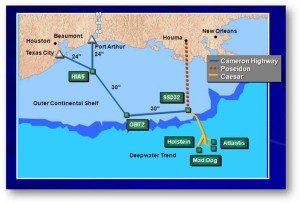

- CAMERON HIGHWAY OIL PIPELINE SYSTEM (CHOPS)

Ship Shoal 332 to Texas City and Port Neches – GOM

Overall Project Scope

Cameron Highway Oil Pipeline System (CHOPS) is a new major oil transportation system in the Gulf of Mexico with two major terminals located in southeast Texas. The 380-mile pipeline system delivers up to 500,000 barrels of oil per day from deep water production sites in the southern Green Canyon and western Gulf of Mexico areas to onshore terminals in Texas City and Port Neches, Texas areas.

The system consists of a 30-inch diameter pipeline originating at a new platform in Ship Shoal 332 in 438 feet of water and extending 113 miles west to an existing platform in Garden Banks 72 in 517 feet of water. From the GB 72 platform, the 30-inch pipeline will go 126 miles in a northwesterly direction to new platform in High Island A5 in 63 feet of water.

At HI A5, the pipeline system splits into two 24-inch diameter pipelines. One pipeline extends to a drilled shore approach near Sabine Pass and then goes onshore to the Port Neches area, a total distance of 70 miles. The other 24-inch segment goes to a drilled shore approach to Bolivar Peninsula and then the pipeline goes through Galveston Bay to terminal points in Texas City, a total distance of 65 miles.

Along its offshore route, the pipeline system crosses approximately 70 existing pipelines and required two horizontal directional drill crossings and an additional 22 directional drills along the bay and onshore routes.

Enerfac’s Scope of Work

Energy Facility® provided services for permitting, detailed design of pipelines, project management, and project engineering support. The following tasks were performed by Energy Facility® personnel:

- Prepared detailed cost estimates

- Permitting & Regulatory Compliance

- Project tracking and controls

- Performed pipeline engineering, detailed design, and drafting

- Prepared bid packages and evaluated and negotiated contracts for onshore and offshore construction activities

- Provided project and construction management and engineering support

[/one_half_last]

Fatal error: Allowed memory size of 134217728 bytes exhausted (tried to allocate 8388608 bytes) in /home/sxwmc4l67hv1/public_html/wp-includes/class-wp-comment.php on line 211